The EVO III hybrid press brake is a CNC-controlled 6-axis machine designed specifically for precision bending, characterized by its silent operation and remarkably low energy consumption. This innovative machine achieves a seamless balance between ergonomics, aesthetics, and functionality, offering operators a unique experience while fulfilling social responsibility through environmentally friendly production practices. Engineered with environmental mindfulness, EVO III delivers not only precision and speed, but also top-tier bending results of the highest quality.

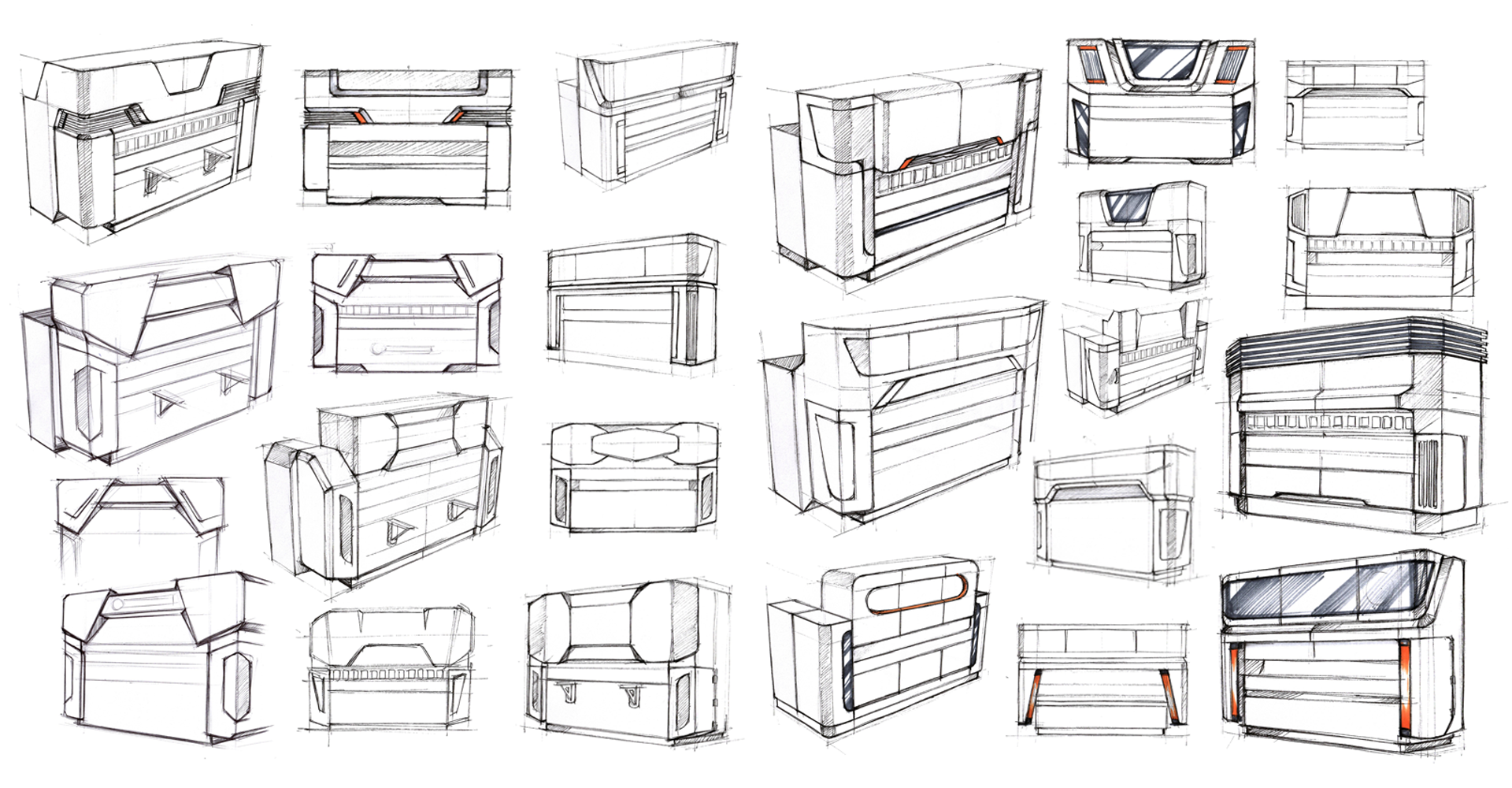

The goal of a greener, quiter and more flexible machine was the initial motivation. The machine was intended to have a striking appearance that significantly differentiated it from its competitors and reflected its innovative features.

The brand area included LED status lights adds an eye-catching appearance to the product and reinforces the user’s relationship with product. The matte aluminium gray frame created with flowing surfaces creates a striking contrast with the glossy black flat area. The edge parts of the frame are produced by plastic injection and middle parts by aluminium extrusion.

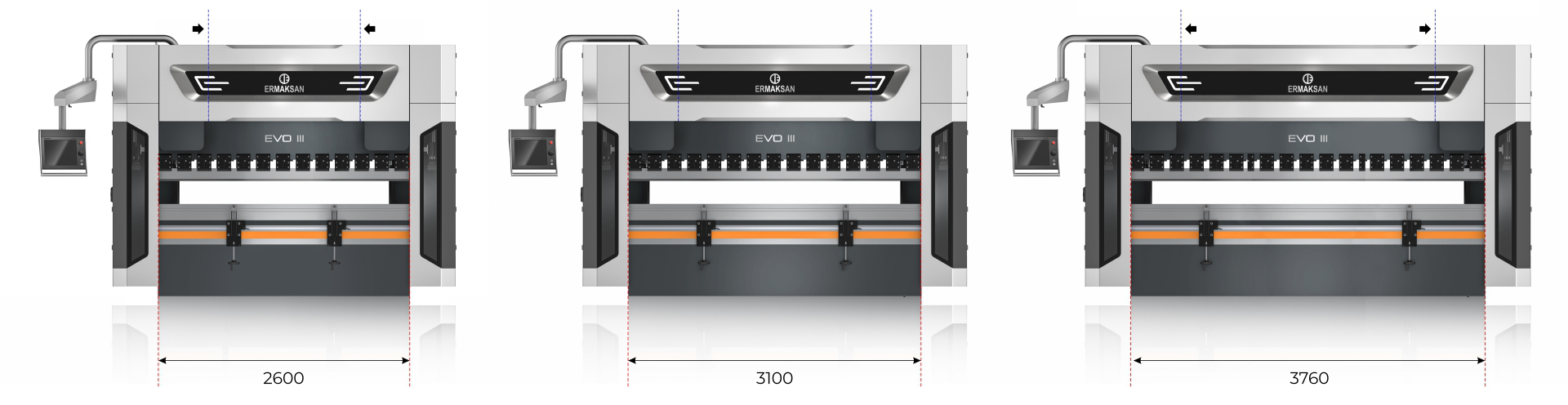

EVO III can be produced in different sizes according to changing requirements. Thanks to the modular brand area that adds flexibility to the design, EVO III can be easily adapted to different size options without losing its design consistency.