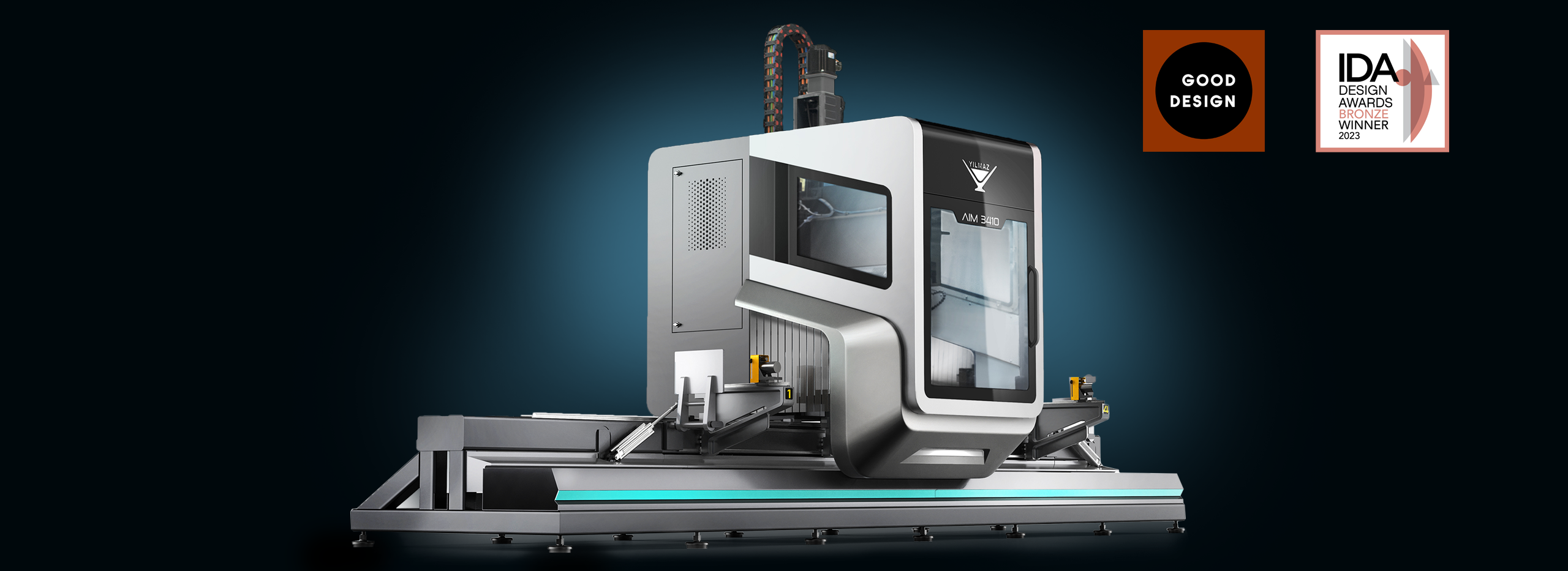

AIM 3410 is a CNC controlled 4-axis machine designed specifically for machining all types of aluminium & PVC profiles.

As a result of widespread use of aluminium profiles in various industries, the demand for CNC machines has increased. The AIM 3410 was designed with the aim of producing a faster, lighter, more compact and more affordable machine optimized to meet needs of industry.

By using composite material part ( RTM production method ) with an innovative approach in machine design, cabin weight has been reduced, user safety has been increased and a dynamic form which can not be produced traditional sheet metal production methods has been gained.

The difference of the AIM-3410 from its competitors is its distinctive appearance which is compatible with its functions and responds to the tastes of its target audience in machining industry. The chasis which has been lowered in height to facilitate material loading and the moveable cabin create a harmonious contrast in size. The outer cover made of composite material, surrounds the mobile cabin with flowing and continuous surfaces in order to give product a dynamic appereance.

Composite cover also acts like a bumper in order to protect user from possible clashes. Warning light on moving cabin reflects the working area border of the movable cabin on the floor. Thanks to the low height chasis and the clamps which are specially designed for this machine on appropriate position, the operator can load the profiles easily. The electrical section is located behind the cabin in order to reduce the total area occupied by the product and to facilitate the wiring operations. The door of the machine is kept as large as possible to provide a better control and service area to the user.

By loading this video, you agree to the privacy policy of Youtube.